When it comes to packing, a box’s design may have a big influence on the usefulness and aesthetics of the goods within. Seal end boxes stand out among the many packing solutions because they combine robustness and convenience in an exceptional way. These adaptable boxes are perfect for a variety of industries, including manufacturing and retail, because they provide a host of advantages. This post will discuss the special qualities of seal end boxes, their advantages in terms of design, and the reasons they are a great option for your packing requirements.

Understanding Seal End Boxes

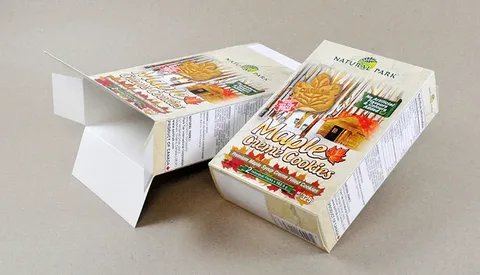

Seal end boxes are characterized by their distinctive design, which includes flaps that are sealed on both ends of the box. This design creates a secure enclosure that protects the contents from external damage while ensuring that the package remains tamper-evident. The seal end box design is versatile and can be customized to fit various sizes and styles, making it suitable for a wide range of products.

The primary components of a seal end box include the front, back, and side panels, as well as the top and bottom flaps. These boxes are often made from sturdy materials such as corrugated cardboard or paperboard, which provide the necessary strength to safeguard the contents during transit and storage.

The Strength of Seal End Boxes

The longevity of seal end boxes is one of its main benefits. The box’s structural integrity is strengthened by the seal end design, which guarantees that stacking and hard handling won’t jeopardize the contents’ safety. Strong protection from impacts, moisture, and other environmental elements that can harm the goods within is provided by the sealed ends.

Industries that handle big or fragile objects benefit greatly from seal end boxes’ robustness. Pharmaceuticals, electronics, and cosmetics, for instance, frequently need packaging that can provide both stability and protection. Seal end boxes efficiently satisfy these requirements by offering a dependable option for a range of product kinds.

Convenience and Usability

In addition to their strength, seal end boxes offer a high level of convenience for both manufacturers and consumers. The design of these boxes allows for easy assembly and efficient packing processes. The pre-folded panels and sealed ends simplify the packaging process, reducing the time and labor required to prepare each box.

Furthermore, seal end boxes are designed with user convenience in mind. The easy-to-open flaps and secure closure mechanisms make it simple for consumers to access the product inside without struggling with complicated packaging. This user-friendly design enhances the overall customer experience and can contribute to positive brand perception.

Customization Options

Because seal end boxes are so adjustable, companies may customize the packaging to meet their own requirements. Options for customization include different finishes, sizes, and forms in addition to printing and branding components. Because of this versatility, companies may design packaging that complements their brand identity while still satisfying practical needs.

For instance, businesses may select from a variety of finishes, such glossy or matte coatings, to have the desired visual impact. Furthermore, logos, product details, and promotional messaging can be included with custom printing to increase brand awareness and draw in customers.

Sustainability Considerations

In today’s eco-conscious market, sustainability is a crucial factor in packaging design. Seal end boxes can be made from recyclable or biodegradable materials, making them an environmentally friendly choice. By opting for sustainable packaging solutions, businesses can reduce their environmental footprint and appeal to environmentally conscious consumers.

Using recycled materials in the production of seal end boxes not only conserves resources but also supports a circular economy. This approach aligns with the growing demand for sustainable practices and can contribute to a positive brand image.

Applications Across Industries

Seal end boxes are adaptable and useful in a range of sectors. They are appropriate for packing a variety of goods because of their sturdy construction and adaptable characteristics, such as:

Retail Products

Food goods, cosmetics, and electronics are among the things that seal end boxes are frequently used for. The items are guaranteed to stay undamaged and safe both in transit and on store shelves thanks to the tight closure.

Pharmaceuticals

Seal end boxes offer a safe and tamper-evident way to packaging boxes drugs and other health items in the pharmaceutical sector. Sensitive materials are kept safe from infection and harm thanks to the sturdy packaging.

E-commerce

Seal end boxes provide an efficient and dependable packing solution for sending goods to clients. The design that is simple to seal makes packaging more efficient.

Conclusion

Seal end boxes are a great example of how to combine use and robustness in package design. Their robust design, intuitive functions, and adaptable choices provide them a highly advantageous solution for enterprises operating in several sectors. Businesses may improve their packing options, safeguard their goods, and provide customers a satisfying experience by investing in seal end boxes.

Whether you need to package prescription drugs, retail goods, or e-commerce shipments, seal end boxes provide a stable and adaptable solution that satisfies aesthetic and functional needs. Accept the benefits of seal end boxes and take your packing approach to the next level.

Personal Finance and Attractive Interest Rates Unlock Smart Savings with Low Rates and Expert Financial Tips

Personal Finance and Attractive Interest Rates Unlock Smart Savings with Low Rates and Expert Financial Tips